Equipment Introduction:The spiral freezing machine is an energy-saving fast freezing equipment with compact structure, wide a

Equipment Introduction:

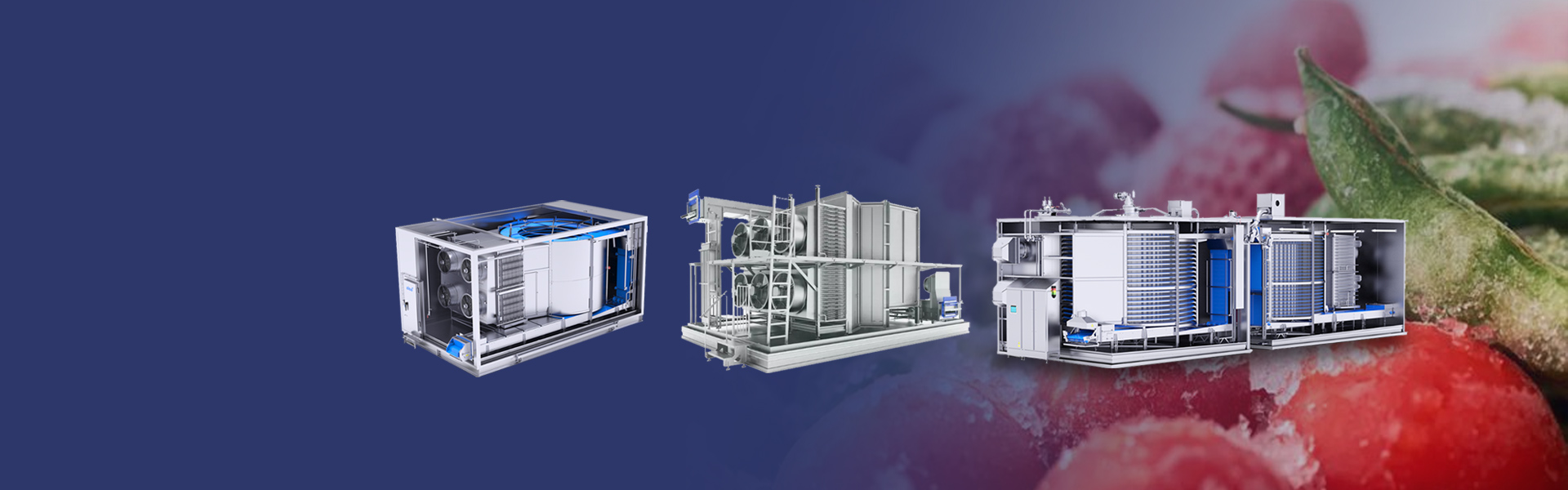

The spiral freezing machine is an energy-saving fast freezing equipment with compact structure, wide applicability, small footprint, and large freezing capacity. The spiral freezer mainly consists of a transmission part, an evaporator, a storage plate, a refrigeration unit part, and an electrical device.

The transmission part is composed of a transmission motor, a mesh belt, a rotating tower, and an independent frequency converter; The evaporator is composed of stainless steel and aluminum fins, arranged with variable fin spacing to ensure smooth air circulation. The evaporator exhaust pipes can be aluminum or copper pipes; The storage board is made of stainless steel; The electrical system consists of a stainless steel electrical box and an intelligent control device; The refrigeration unit consists of a compressor, pressure vessel, refrigeration components, electrical control, and various valve components.

Application field:

Suitable for rapid freezing of individual particles or small pieces of food, and also suitable for freezing large frozen products such as fast food, whole chicken, whole fish, etc. Double spiral freezing device, feeding from the bottom and discharging from the bottom, can connect with the customer's front and rear processing production lines on the ground, making it convenient to use.

Technical features:

1. Compared to the tunnel structure design, it is more optimized, with a smaller footprint and higher quick freezing efficiency, meeting the freezing requirements of high-capacity customers.

2. Higher airtightness, less contact with the outside world, higher refrigerant utilization rate, more cost saving, and maximized gas utilization during discharge.

3. Single screw and double screw machines can be customized according to customer production requirements to solve the problem of product freezing capacity.

4. The length of the freezing chain is longer, which increases the freezing contact time, freezing quality, and production per unit time.

5. There are more diverse ways to import and export materials, including low input and low output, high input and low output, and low input and high output, which can meet the different needs of different frozen materials and make it easier for seamless docking between different production lines.

6. The air circulation system allows the refrigerant to circulate in the box for faster freezing and higher efficiency.

7. The internal cylindrical freezer largely saves space, reduces space waste, and increases utilization.

8. The stacked hub operation structure makes the mesh belt operation more stable, reduces the occurrence of faults, and makes the equipment more stable.

9. Adopting an axial flow fan with large air volume, high air pressure, vertical blowing, large windward area, and short freezing distance; Multiple air flow modes, uniform air flow and temperature distribution, no air flow dead angle, high heat exchange efficiency, short freezing time, low dry consumption, high yield; The ice crystals are small, with less cell damage, and the product loses less water after thawing. The texture and taste are both excellent.

Home

Home

Product

Product

News

News

Contact

Contact